When it comes to specifying builders work openings for modern construction projects, the debate often comes down to one critical question: 3 sided or 4 sided?

As specialists in offsite drywall production and pre-cut structural components, Drywall Pro-Cut has worked with leading contractors to simplify this decision-making process. This guide breaks down the differences, advantages, and ideal use cases for each type, helping you choose the most efficient and compliant solution for your project.

What Are Builders Work Openings?

Builders work openings, often referred to as BWIC or simply “builders work holes,” are pre-designed access points within drywall systems. These allow for seamless integration of mechanical and electrical services such as ductwork, pipework, and wiring.

They are essential in both new builds and refurbishments, especially where accuracy, speed, and safety are a priority.

Why Is the Number of Sides Important?

The design of a builders work opening affects not only the installation process but also future maintenance access, fire safety, and acoustic integrity.

A 3 sided builders work opening leaves one side open – typically the top or bottom – making it ideal for exposed service runs.

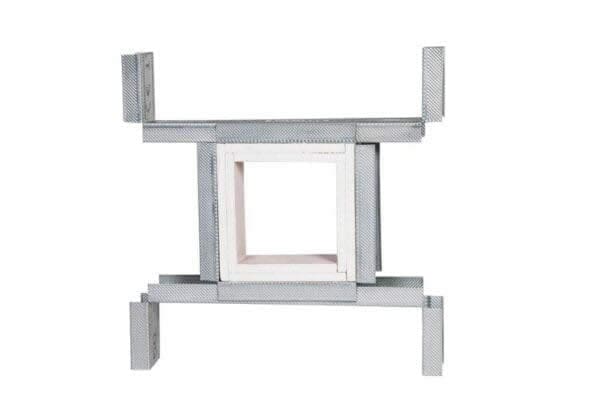

A 4 sided builders work opening, on the other hand, provides full enclosure, offering greater protection and visual uniformity.

1. 3 Sided Builders Work Openings: When Less is More

Three-sided options are often chosen for flexibility. The open side facilitates fast installation around pipes or cables that have already been installed. These are popular in settings where services are accessible from ceilings or floors.

Key Benefits:

- Easy to install around existing services.

- Faster fit-out time.

- Less material required.

- Better for exposed corners or junctions.

- Ideal for adjustable access points and modular applications.

Project managers often favour 3 sided builders work openings where speed and adaptability are crucial, particularly in retrofit or refurbishment scenarios.

2. 4 Sided Builders Work Openings: For Total Enclosure

If your project demands sealed, uniform access points, 4 sided builders work holes are the answer. Their enclosed structure makes them perfect for areas requiring higher fire safety or acoustic performance, such as hotels, healthcare facilities, or student accommodation.

Key Benefits:

- Full containment of services.

- Greater protection from dust and debris.

- Improved fire and sound performance.

- Stronger, more durable frame.

vIdeal for twin wall openings.

These openings are available in both modular and adjustable formats, allowing for pre-set sizing or on-site tweaks depending on your site requirements.

Modular vs. Adjustable: Flexibility Built In

Both 3 and 4 sided formats are available in modular and adjustable options. Modular units are factory-fabricated and pre-sized for consistent, rapid installation. Adjustable models, meanwhile, give site teams the flexibility to adapt openings around unexpected layout changes.

Whether you’re working on a bespoke architectural project or large-scale commercial build, this flexibility can be a game-changer.

Twin Wall Compatibility and Acoustic Integrity

If your project uses twin wall drywall systems, both 3 and 4 sided openings can be tailored for that setup. Our twin wall options are designed to maintain acoustic and fire performance between drywall layers, while allowing for service access without compromising structural integrity.

Choosing the Right Opening: Ask These Questions

Before placing your order, consider these questions:

- Are services already installed or will they be installed after walls go up?

- Will the access need to be adjusted on site?

- Is the area high-risk for fire or noise?

- Does the project require twin wall installation?

- Will the openings be visible or concealed?

Our team at Drywall Pro-Cut can assist with determining the best solution for your application.

Offsite Production Saves Time and Money

Whether you choose 3 or 4 sided, manufacturing your builders work openings offsite significantly improves speed, safety, and sustainability. We pre-label and package every component to match your project layout – ensuring that each piece goes exactly where it’s needed, when it’s needed.

This approach eliminates guesswork, minimises waste, and improves labour efficiency on site.

Why Drywall Pro-Cut?

We’re not just a manufacturer – we’re your partner in precision drywall solutions. With patented technologies and strict quality control, we deliver builders work openings that meet fire, acoustic, and structural standards.

Our promise is clear: faster installs, fewer errors, and more confidence on every site.

FAQs

What’s the difference between 3 and 4 sided builders work holes?

A 3 sided opening is open on one side for easy service access, while a 4 sided opening fully encloses the cavity.

Are these openings compliant with fire and acoustic regulations?

Yes. Our 4 sided and twin wall options are engineered to meet rigorous building safety standards.

Can you customise builders work openings?

Absolutely. We offer both modular and adjustable options to meet the unique specs of your site.

What projects benefit most from 4 sided openings?

Hotels, healthcare facilities, and any setting with high acoustic or fire safety demands.

How does offsite production benefit contractors?

Offsite components reduce installation time, labour needs, and waste while improving consistency and site safety.

Final Thoughts

3 sided or 4 sided – whichever route you take, make sure it’s tailored to your site conditions and compliance requirements. At Drywall Pro-Cut, our team can guide you through the specification process and deliver pre-fabricated solutions that keep your project on time and on budget.

Ready to simplify your next build?

Explore our full range of builders work openings today.

Get in Touch

Have questions or need a tailored drywall solution for your next project?

Email: enquiries@drywallpro-cut.co.uk

Phone: 01827 213201