In any commercial construction project, precision is key. One often overlooked but vital component is builders work openings. Also referred to as builders work holes, these access points support mechanical and electrical systems and ensure smooth project delivery.

At Drywall Pro-Cut, we specialise in offsite-manufactured drywall solutions, including builders work openings (BWIC) tailored to your specifications. In this guide, we’ll explain their purpose, benefits, types, and how they transform project workflows.

What Are Builders Work Openings?

Builders work openings are purpose-cut spaces within drywall assemblies, created to allow safe passage and access for services such as:

- Plumbing.

- Electrical wiring.

- HVAC and ductwork.

- Fire protection systems.

These components are integral for M&E (mechanical and electrical) installation. Without correctly positioned openings, installers would need to cut through drywall manually – increasing error, dust, and cost.

Why They Matter in Commercial Projects

When you’re running a fast-paced build, time is your biggest asset. Builders work openings, especially when manufactured offsite, offer consistency and precision that on-site methods can’t match.

They reduce project risk, speed up installation, and help meet evolving compliance requirements like the Building Safety Act.

Key Benefits:

- Reduced on-site labour and cutting.

- Improved project timelines.

- Guaranteed compliance with M&E layouts.

- Minimised material waste.

- Enhanced site safety through reduced tool use.

Understanding BWIC in Context

BWIC stands for Builders Work in Connection. It encompasses all provisions made for M&E systems within building structures.

For project managers, understanding BWIC means:

- Being proactive in planning service routes.

- Coordinating drywall installation with M&E teams.

- Minimising rework and client dissatisfaction.

Builders work openings are the physical manifestation of this coordination. They are not an afterthought – they are part of the structure’s design.

Types of Builders Work Openings We Offer

At Drywall Pro-Cut, we provide a diverse selection of openings to suit any build environment. Our systems are designed to reduce time on site, boost quality, and support a wide range of specifications:

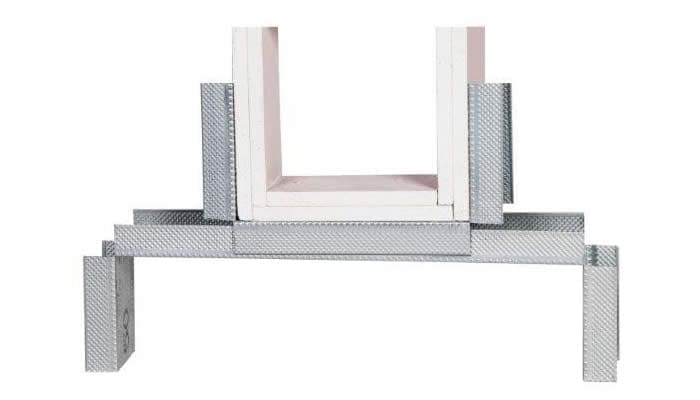

1. 3-Sided Builders Work Openings

Ideal for corner installations or semi-exposed systems. They offer flexibility without compromising structural integrity.

2. 4-Sided Builders Work Openings

Fully enclosed access points perfect for ductwork and complex utility installations.

3. Twin Wall Builders Work Openings

Designed for projects needing high acoustic or fire performance. These openings have dual-board systems with insulation for added safety and comfort.

4. Modular & Adjustable Variants

Our modular versions are pre-assembled for quick install, while adjustable formats offer on-site flexibility.

Why Choose Offsite Production?

At Drywall Pro-Cut, we produce builders work openings using offsite drywall manufacturing. This ensures every component meets precise tolerances.

Our Approach:

- Receive your M&E drawings.

- Cut and label each opening according to room/zone.

- Deliver pre-packaged for quick install.

- Provide marked-up plans for reference.

This removes guesswork for installers and provides peace of mind for project managers. It also means faster fit-outs and fewer on-site disruptions.

Real-World Application: Mechanical and Electrical Integration

Builders work holes are a bridge between structure and services. Without them, integrating electrical and mechanical elements becomes chaotic. That’s why our clients often order openings in bulk for high-density service areas.

By coordinating with your M&E teams, we ensure each component fits first time-streamlining coordination between trades.

How Builders Work Openings Improve Drywall Access

Easy drywall access isn’t just about convenience. It’s about future-proofing your project. Service maintenance becomes faster and safer when you plan for it from day one.

Our access solutions provide:

- Clean, removable panels.

- Alignment with aesthetic finishesv

- Long-term savings on maintenance.

Why Drywall Pro-Cut is Your Best Choice

We’ve supported some of the UK’s most complex commercial builds by delivering reliable drywall access systems, including builders work openings, with precision.

Whether you need a single bespoke solution or a full-scale rollout for a multi-floor project, we’re ready to help you meet your deadlines and compliance goals.

Explore our Builders Work Openings product range:

Drywall Pro-Cut Builders Work Openings

FAQs

1. Can you customise openings to exact site drawings?

Absolutely. We manufacture to your measurements and coordinate around your installation plans.

2. Do you supply mark-up drawings?

Yes. All offsite openings include marked-up documentation for easy onsite use.

3. What’s the turnaround time?

Depending on volume and complexity, we aim to supply within standard lead times aligned to your project needs.

4. How do I avoid conflicts with M&E layouts?

By engaging with Drywall Pro-Cut early, you can ensure all openings are mapped and pre-checked against final layouts.

5. Are your products Building Safety Act compliant?

Yes. Every solution we deliver meets or exceeds the latest UK safety and compliance standards.

Final Thoughts

Builders work openings aren’t just practical – they’re essential. In today’s construction environment, where time is tight and compliance is critical, getting these right from the outset saves more than money – it ensures build integrity and client satisfaction.

From construction access points to mechanical and electrical integration, these humble components play a big role in modern construction success.

Get in Touch

Have questions or need a tailored drywall solution for your next project?

Email: enquiries@drywallpro-cut.co.uk

Phone: 01827 213201