In the fast-paced world of commercial construction, flexibility and compliance are no longer luxuries – they’re expectations. As leading drywall specialists, Drywall Pro-Cut understands that modern contractors need more than traditional access points. That’s why we’ve embraced the future with modular builders work openings, adjustable formats, and twin wall designs.

What Are Modular Builders Work Openings?

Modular builders work openings are prefabricated access points built offsite for integration into drywall systems. Unlike traditional on-site cutting methods, these panels are manufactured to precise specifications, reducing waste and enhancing installation efficiency.

Each modular panel is designed with the mechanical and electrical trades in mind. Whether you’re routing pipework, cable trays, or air ducts, modular openings ensure consistent access while meeting regulatory compliance.

The Advantages of Going Modular

Opting for modular drywall access solutions offers multiple benefits:

- Speed: Offsite fabrication accelerates your on-site workflow.

- Accuracy: CNC-guided cuts minimise measurement errors.

- Consistency: Each unit is uniform, ensuring a clean, professional finish.

- Cost-Efficiency: Reduced on-site cutting means less labour, waste, and risk.

For project managers, these advantages translate into fewer headaches, smoother coordination, and more predictable project timelines.

Adjustable Openings: Flexibility Meets Function

One of the most practical innovations in drywall construction is the adjustable opening. These are ideal for projects where final service routes are yet to be confirmed.

Adjustable builders work holes can expand or contract to accommodate last-minute changes in pipe diameter or cable tray width – perfect for dynamic building environments. And with Drywall Pro-Cut’s precise offsite cutting, these solutions maintain structural and fire-rated integrity while offering freedom on site.

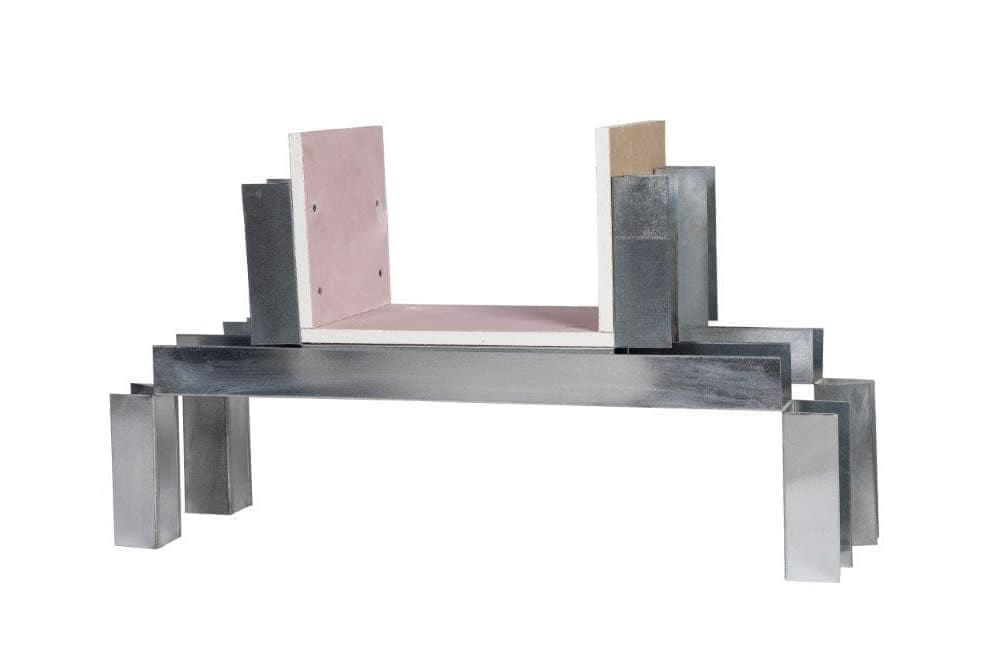

Twin Wall Designs: Performance Beyond the Surface

Twin wall builders work openings are crafted from two parallel plasterboard layers separated by insulation.

This configuration offers:

- Improved sound attenuation.

- Superior fire resistance.

- Robust structural support.

Twin wall drywall systems are particularly valuable in high-traffic or noise-sensitive areas, such as hospitals, hotels, and mixed-use developments. Our twin wall designs ensure your installations meet performance criteria without compromising on finish.

Fire-Rated Openings: Compliant and Controlled

In commercial construction, fire-rated openings are non-negotiable. Drywall Pro-Cut provides pre-engineered fire-rated solutions that meet regulatory demands and simplify on-site compliance checks. Every component is labelled for traceability and pre-cut to reduce risk during installation.

By taking control of compliance through offsite fabrication, project managers can confidently pass inspections and reduce rework.

Real-World Use Cases

1. Healthcare Projects

Twin wall systems reduce noise in hospitals while maintaining fire barriers in utility corridors. Adjustable panels accommodate unexpected last-minute service revisions.

2. Hotels & Student Housing

Modular drywall openings streamline repetitive installations across multiple floors, ensuring uniformity and quick installation – ideal for tight schedules.

3. Mixed-Use Developments

Builders work openings support M&E access behind shared walls. The ability to pre-plan routes improves collaboration across trades and boosts project efficiency.

Offsite Manufacturing: Why It Works

Drywall Pro-Cut uses offsite drywall manufacturing for every builders work opening. We believe pre-cut, precision-made access points are the future for scalable, compliant, and clean construction.

This model reduces the reliance on skilled labour for site cutting, increases safety by limiting dust and saw use, and reduces waste thanks to precision materials management.

FAQs

1. Can modular builders work openings be customised to project-specific M&E requirements?

Absolutely. Drywall Pro-Cut offers custom dimensions, pre-labelled packaging, and technical drawings to suit any project specification.

2. Do twin wall designs affect installation time?

They often reduce it. Though slightly heavier, twin wall systems come pre-built for seamless integration, eliminating the need for separate fireproofing layers.

3. What’s the difference between modular and adjustable openings?

Modular openings are pre-built to spec, ideal for consistency. Adjustable openings offer flexibility on-site when final service layouts aren’t fixed.

4. Are all designs compliant with fire and acoustic regulations?

Yes. All Drywall Pro-Cut openings meet or exceed UK Building Safety Act requirements and manufacturer specifications.

5. Can we use these solutions in refurbishment projects?

Absolutely. Our modular and adjustable systems are ideal for retrofits, offering clean access points with minimal structural disruption.

Partnering with Drywall Pro-Cut

We are more than a supplier – we are a strategic partner. From planning to delivery, our team works closely with yours to ensure all builders work openings meet quality, performance, and safety expectations.

With our patented offsite drywall solutions and modular innovation, you gain not just a product, but a powerful tool to enhance your project delivery.

Your Next Step in Construction Evolution

At Drywall Pro-Cut, we’re committed to moving the industry forward. With modular builders work openings, adjustable panels, and twin wall designs, we offer solutions that streamline your build, simplify compliance, and raise your standards.

Ready to upgrade your construction access strategy?

Let’s talk about how we can help.

Get in Touch

Have questions or need a tailored drywall solution for your next project?

Email: enquiries@drywallpro-cut.co.uk

Phone: 01827 213201